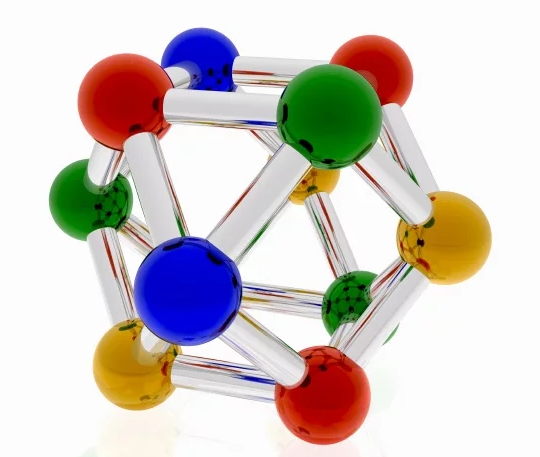

Janus particles named after Roman god Janus who was illustrated with two faces, one looking to the future, and the other to the past. Pierre-Gilles de Gennes mentioned the term Janus particle in his Nobel lecture on soft matter in 1991. Janus particles are synthesized by joining two or more different materials together. Each material imparts a unique and useful quality to the particle; therefore, one Janus particle can display multiple properties and functionalities. It is this fundamental asymmetry that makes Janus particles a powerful tool in biotechnology for biosensing, bioseparation, self-assembly, drug delivery, and much more. This blog post will summarize a lengthy and informative reviewarticle of the same title that was published in Chemical Reviews in 2013.

Synthesis and self-assembly:

Masking is perhaps the oldest method of synthesizing Janus Particles (JPs). It starts with homogeneous particles that are embedded into a planar surface, effectively masking one hemisphere of each particle. The exposed hemisphere is chemically modified with ligands, antibodies, small molecules, functional moieties, metallic coatings, superparamagnetic nanoparticles, etc. Then, the planar surface is removed. The free particles then have two different surfaces with varying functionalities, and can be classified as Janus Particles.

Another synthesis method is the self-assembly of Janus Particles into a multitude of shapes including micelles, strings, helices (single and double), bilayers, tetragonal bilayers, coexisting phases of vesicles and bilayers. The particles can be rods, spheres, disks, and anything in between. Self-assembly in solution is usually governed by pH or the hydrophobic/hydrophilic nature of the materials comprising the particles. The self-assembly of block copolymers in solutiontakes advantage of the differences in solubility of the polymer blocks. For example, a block copolymer can be formed with a chunk of hydrophilic polymer A on one end attached to hydrophobic polymer B in the middle, and hydrophilic polymer C at the other end. When this polymer is placed into an aqueous solution it will self-assemble into a tightly packed structure with a hydrophobic core of polymer B and hydrophilic polymers A and C on the surface. This synthesis method doesn’t necessarily create perfectly defined hemispheres of A and C, but it does produce a particle with varying properties.

A newer method for synthesizing Janus Particles is electrohydrodynamic jetting. Two or more different polymer solutions are fed in parallel through a small opening and into an electric field. The solutions simply flow next to each other; they do not mix. The electric field stretches the parallel flow until itis too thin to sustain and itbreaks into small spherical or cylindrical droplets.Each droplet is composed of unmixed regions of the different polymers. Altering the flow rate, viscosity, concentration, and conductivity of the polymer solutions as well as manipulating the applied electric field affords control over the size and the shape of the droplets as well as the relative amounts of each polymer. Functional moieties can be added to the polymer solutions to create functionalized Janus Particles.

Physical properties

The anisotropic and asymmetric nature of Janus Particles endows them with exciting physical and chemical properties. One useful property is their interfacial activity, especially between hydrophilic and hydrophobic boundaries. In one type of biphasic JP, one material may be hydrophilic and the other hydrophobic, so the particle itself can “walk the line”. This property makes Janus particles useful as emulsifiers and stabilizers. Self-assembly at interfaces may also be harnessed for a variety of applications.

Janus Particles can have anisotropic optical properties. One face can have fluorescent tags or quantum dots while the other is reserved for targeted binding moieties, paramagnetic nanoparticles, or other chemistries. Some Janus Particles have different fluorescent colors on different faces, meaning that the optical properties change as the particle rotates. These anisotropic optical properties introduce tunability and functionality that simply can’t be achieved with isotropic particles.

The hemispheric nature of Janus Particles introduces the possibility of self-propulsion. For example, one side of the Janus Particle could be coated with platinum, which is a catalyst for the production of oxygen gas from hydrogen peroxide. Since the gas production is only on one side of the particle it can propel the particle through solution.

Applications

Janus Particles have many current and potential applications inbiosensing, pathogen detection, imaging,bioseparation, cell labeling, targeted drug delivery, controlled drug release, e-ink readers, colored displays, tissue engineering, and much more.

One example is the combination of paramagnetic nanoparticles and quantum dots into a single Janus Particle. (link to blog post ‘create fluorescent and magnetic Janus particles) This JP can be used both to isolate a target by magnetic separation and also to provide a quantitative readout of binding efficiency or target concentration.

The anisotropic cell-cell signaling and attachment introduces the possibility of manipulating the self-organization and growth of cellular colonies and tissue.

Bicololored Janus Particles are used for electronic ink readers. The orientation of the JPs is controlled by an electric field, which causes them to display a black or white face. Janus Particles could potentially be used to create multicolor displays controlled by an electric field.

In summary, the asymmetric nature of Janus particles gives them anisotropic properties, which makes them a flexible and exciting tool for a number of applications. Their power lies in their ability to combine multiple functionalities and chemistries into one small package. The topics covered here are only a short summary of the synthesis, self-assembly, physical properties, and applications of Janus particles. For more information and detailed explanations look to the review article that inspired and informed this blog post.

Create fluorescent and magnetic Janus particles

A Janus particle is a nanoparticle with a surface that has two or more different physical properties. This allows multiple types of chemistry to occur on the same particle. The Janus particles produced by this new microfluidic technique have both fluoresce

Quantum dots (QDs)

Quantum dots (QDs) are an exciting new development. They are nano-crystals that are quantum-confined by their size. This means that certain sizes of quantum dots are only capable of emitting one wavelength of light. Therefore, quantum dots can be synthesized to fluoresce sharply at a single color regardless of how much light they absorb. Combining the properties of quantum dots with the properties of magnetic nanoparticles creates a powerful bioassay tool.

Synthesis of QD-doped magnetic nanoparticles (MNPs) has been attempted before by using layer-by-layer assembly or encapsulation techniques. These techniques have not been very successful. One problem is that the QDs can leak out in harsh chemical environments. Another problem is that encapsulation techniques are time-consuming and result in particles with a very large size distribution. A large size distribution is undesirable because it introduces variability into the magnetic separation process and can lead to irreversible bead aggregation. A narrow size distribution and uniform particle size is extremely desirable. A new microfluidic technique for the generation of QD magnetic nanoparticles with a narrow size distribution has recently been developed.

All microfluidic techniques allow for controlled preparation of particles by combining a microfluidic emulsification with a solidification mechanism. Many different types of bead coatings are compatible with this technique. However, the solidification mechanisms used in the past relied on UV exposure or heating treatment.

Alginate hydrogel chemistry

This new technique does not use excessive heat or any UV treatment, but instead relied on alginate hydrogel chemistry. Briefly, Fe3O4 nanoparticles and CdSe/ZnS QDs are dispersed in separate alginate solutions. The two solutions flow through separate channels and then join together as a co-flow in a focusing channel. The solutions don't mix, they simple flow together. A third continuous flow orthogonal to the co-flow injects a solution of CaCl2, oleic acid, and a small amount of isobutanol. When the third channel hits the co-flow the interaction creates small janus droplets by a shear-rupturing mechanism. The size of the particles is quite uniform, and can be controlled by adjusting the continuous flow rate. As the droplets continue to flow down the channel the Ca2+ diffuses into the droplets and ionically crosslinks the sodium alginate, which causes them to solidify. Alginate hydrogel is a biocompatible material, and the surface contains carboxyl groups that will conjugate to biomolecules to allow surface functionalization of the microbeads.

After the QD-MNP Janus particles were synthesized they were tested in a DNA assay. The particles were functionalized with a complementary coding sequence and incubated with the DNA. The DNA had a green fluorescent molecule. The Janus particle had a red fluorescent quantum dot. After incubation the DNA-particle conjugates were collected by magnetic separation. The isolate was viewed under a fluorescent microscope to examine binding efficiency. It was found that the DNA bound properly because the green fluorescence co-localized with the red fluorescence. The new synthesis technique is easy and functional, and could become a very useful bioassay tool.

Related news

- Biphasic janus particles with nanoscale anisotropy

- Cell separation based on cell density

- Protein a magnetic beads