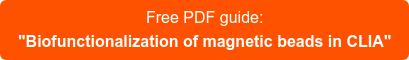

For a successful procedure for the magnetic bead conjugation, there are three important aspects to take in consideration when designing the assay: i) the planning of the conjugation protocol, ii) the density of the functional groups on the surface of the magnetic beads, and iii) the controlled magnetic separation of the beads.

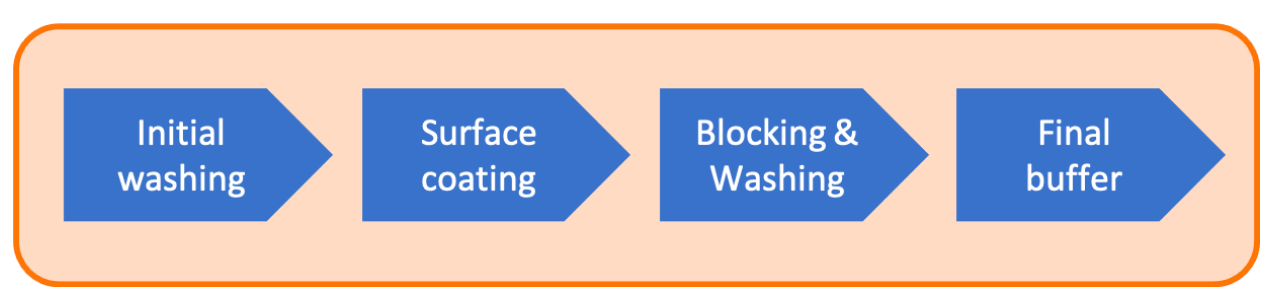

Typical bead conjugation protocol

- First washing step - During this step the buffer in which the beads came is removed because it can contain components that can potentially interfere with the conjugation. Magnetic beads are attracted by a magnetic separator and the initial buffer is removed.. When the bead buffer is removed, the appropriate buffer for antibody or antigen coating is added to the beads.

- Coating the magnetic beads - The magnetic beads are then coated with either antibody or antigen depending on the assay format. The time for this step varies depending on the choice of the chemistry reaction of the bead and the protein to be attached. The optimal length for this step can last one, a few hours or overnight/s. It is important to consider the pH of the buffer used for the coating to make sure it is optimized for the specific isoelectric point of the chosen coating protein. Often coating is done at room temperature or 37 degrees if the protein of choice is stable at higher temperatures.

- Blocking and Washing Steps - Blocking allows that free space or free chemical groups on the bead surface to be bound to prevent non-specific binding . Classic blocking agents are BSA, casein, PEG and glycine, which will bind to the free groups on the bead. Sometimes small amounts of detergent are also used to further prevent or reduce non-specific binding. This step is usually done at room temperature.

- Final buffer - The final buffer for bead conjugation is added to optimize the use of the magnetic beads. It will prevent bead aggregation and help keep the beads stable. This buffer might include blockers and should be optimized for pH and ionic strength. To prevent contamination antimicrobial agents are added, usually in the range of 0.05 to 0.10%.

Influence of bead surface density

The amount of functional groups on the surface of the magnetic beads is an important parameter to take in consideration. This parameter is commonly quantified through the so-called “Parking Area (PA)”. In a coating process, the PA defines the space occupied with the functional groups on the surface of a magnetic bead. From a mathematical point of view, the calculated PA is the reciprocal of the surface charge density. PA is directly related to the bead size (and this to its surface), the density of the solid bead and the amount of the surface functional groups. One of the benefits from knowing the PA, is the ability to select beads of different sizes with similar binding properties.

Controlled magnetic separation during bead conjugation

Modern magnetic separators for magnetic bead separation are able to monitor the separations in real time. This is extremely valuable for the conjugation procedure. Separation of magnetic beads during conjugation should be efficient, avoiding residual stuck of the beads and easy to monitor. Efficiency is achieved when the separation is done quickly, steadily and repeatedly, all of which is a staple of modern magnetic separators. These specifications also reduce beads aggregation. Modern magnetic separators can also allow to scale up small lots to production size lots of conjugated beads as they are available in 10 liter sizes. Finally, modern separators come with the technology to follow the efficiency of the separation in real time on a computer. This gives more control over the conjugation procedure as you can monitor which buffer and conditions are best for your separation and getting consistent quality results. This also provides information between lots prepared of conjugated beads to check the robustness of the conjugation procedure.

Related news

- Moving from Latex Particles to Magnetic Latex Particles

- Aspects of available Chemiluminescent immunoassay (CLIA) kits in the market

- Streptavidin HRP