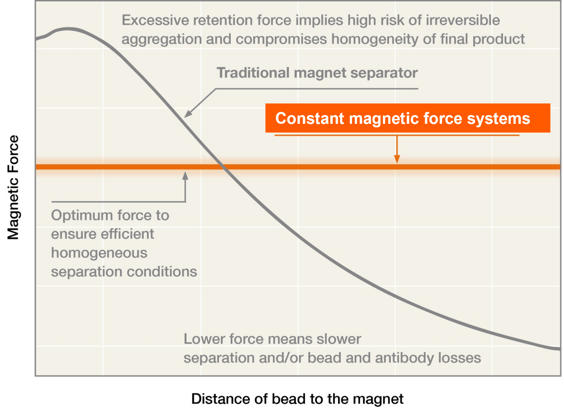

To ensure a consistent biomagnetic separation process, all the magnetic beads should experience the same conditions. Controlling the magnetic force is key to achieving consistency within and between batches, especially when scaling up. Classical magnetic separators generate a magnetic force that is very high on the side of the vessel closest to the magnet but declines rapidly with distance. The magnetic force experienced by beads in the retention area is therefore greatest, while the beads farthest away experience the lowest force.

The difference may seem negligible at small volumes, but at larger volumes, the relative difference in the magnetic force between the retention area and the far side of the vessel increases. This means that the farthest magnetic beads move slower as the vessel diameter increases, while beads closer to the magnet aggregate.

To resolve this issue, the magnetic force must be constant over the entire working volume. In other words, the magnetic force needs to be increased for the most distant beads, but not the ones nearest to the magnet. To do this, a new approach is needed.

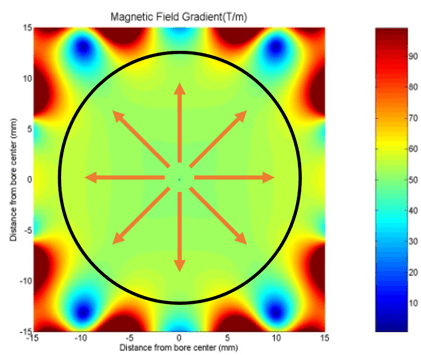

Constant magnetic force separation systems, such as Sepmag, generate a magnetic field pattern with both a high magnetic field and gradient. This is achieved by using permanent magnet arrays, which create the same magnetic force across the entire working volume.

When the magnetic force is constant and radial, the farthest beads are placed at the center of the vessel, much closer than the opposite side in classical separators. A shorter distance and larger magnetic force results in a much shorter separation time for a given volume.

Figure 6.1 Map of the radial constant magnetic force inside an advanced biomagnetic separation system. The color indicates the intensity of the magnetic force, the arrow shows its direction.

Moreover, the radial direction of the force evenly distributes the magnetic beads along all the cylindrical walls of the vessel. This results in a larger retention area, and therefore a lower density of beads. As constant magnetic force allows very short separation times, the value of the force can be minimized when the magnetic beads are prone to aggregation. Minimizing both the retention force and the density of beads at the retention area reduces the risk of clumps forming.

In addition, constant magnetic force systems allow you to specify a force value for different applications. This allows users to choose the best magnetic force for each magnetic bead suspension. For example, when coating magnetic beads to develop an IVD test, if the chemistry means the beads are more prone to aggregation we will need to use a low constant magnetic force to avoid clumps forming. In contrast, when using a very low concentration of nanoparticles for cell isolation we will need to use the highest magnetic force we can technically achieve.

This constant magnetic force approach ensures a consistent process: all beads within a batch experience the same force. It also ensures better batch-to-batch reproducibility. In classical separators, a small difference in the placement of the vessel between batches can have a dramatic effect on separation time and aggregation.

Moreover, having a well-defined magnetic force allows testing of devices with different values. Users can choose the right intensity for a specific application, magnetic bead suspension, and matrix. And, when using permanent magnets, the magnetic force value specified is, by definition, permanent.

Figure 6.2 Showing the relationship between the distance of bead to the magnet and the magnetic force, in constant magnetic force systems (orange) and traditional magnet separators (gray). Magnetic force in traditional separators is highest where the bead is closest to the magnet and declines with distance from the magnet. In constant force systems there is no change in magnetic force with the distance of a bead to the magnet. Magnetic force is also lower closest to the magnet in constant force systems than traditional magnetic separators, which reduces the risk of irreversible aggregation.

The old saying ‘magnetic beads don’t work at large volumes’ is, simply, wrong. If you want to learn what leading IVD-manufacturers already know, this is the e-book for you!

Related news

- Different types of Immunoassays

- DBCO click chemistry: what is it and what are its benefits?

- What is poly dt?