Monitor your biomagnetic

separation process

Change your suspension and monitor the effects

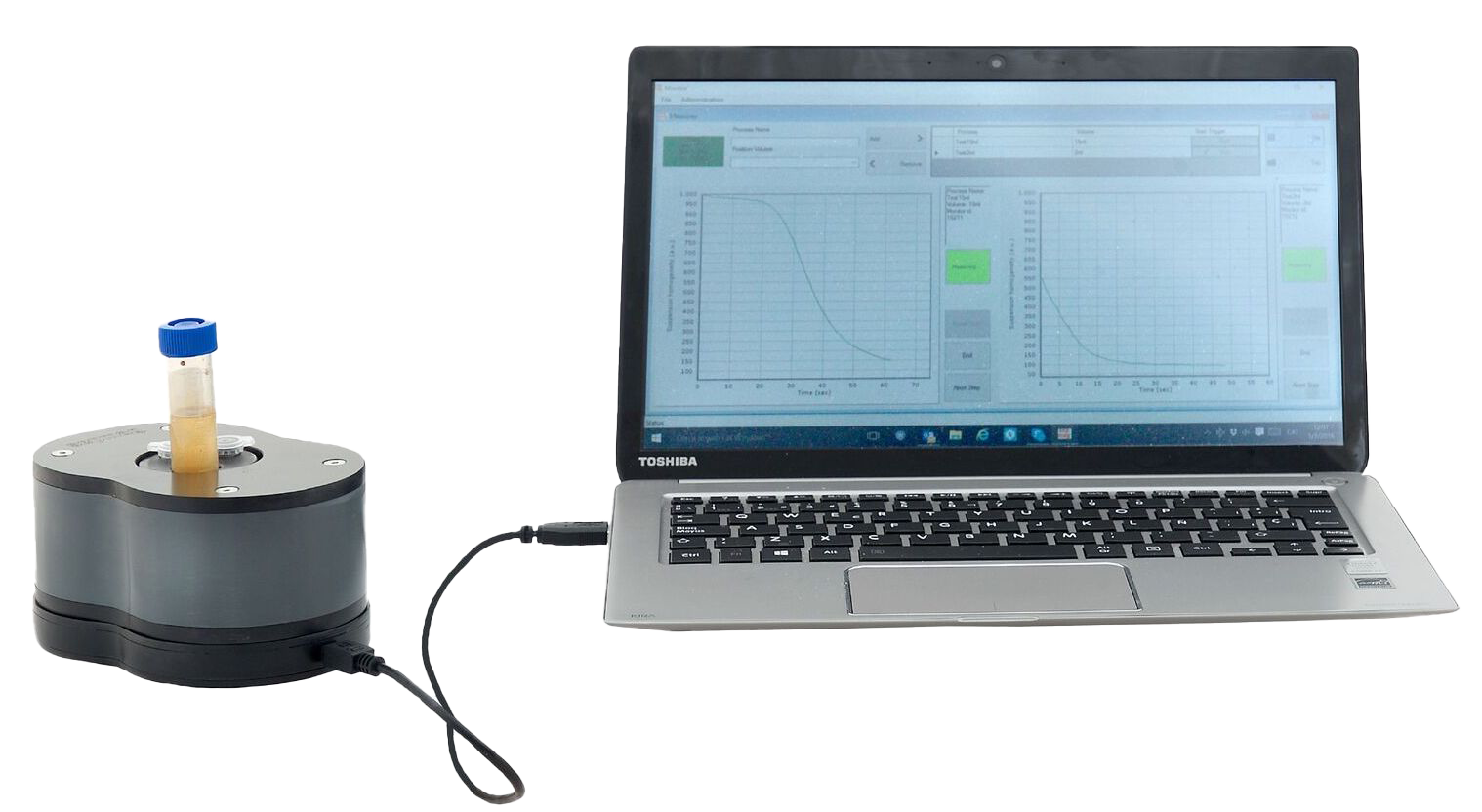

- Monitor in real time

Our MONITOR software & hardware measures the suspension optical changes, displaying its behavior and comparing different compositions. - Well defined magnetic separation condition

Applying a well defined magnetic force over all the sample means variations are only related to suspension characteristics (particles, buffer, ...) - Full scalability

Its well defined separation conditions guarantee a direct transfer to production or larger volumes. Just use a bigger vessel and Sepmag separator. - Safe system

Big magnet can be dangerous. Our systems are designed to operate near computers and avoid risks for the operators.

Systems for R&D and small volumes

Change your suspension and monitor the effects

Sepmag A

Small tubes using MA adaptors and bottles up to 500ml. For scaling up experiments, process validations, or even small batch productions.

The Sepmag A scale-up systems take advantage of the reproducible Sepmag technology in which magnetophoretical conditions anywhere inside the system ring are constant. End-users often need to work with a wide range of volumes, starting with small tubes and increasing sample size when processes are optimized or simply when sample volumes vary.

With the Sepmag A biomagnetic separators users can start working with 1.5, 10 and 50 ml tubes and further scale up to either 200ml (Sepmag A200ml) or 400ml (Sepmag A400ml) volumes. A standard holder for a variety of tube sizes is provided with each system, but customizable adaptors can be supplied to suit user´s requirements.

Processes are monitored and recorded using the MONITOR hardware and software, which enables the operator to explore the effects of bead size, concentration or buffer conditions on the separation process.

Benefits

Explore, monitor and obtain data of your process

Easy comparison between processes and runs

Full recovery of material

Easy scalability

Work with viscous liquids and small particles

Safe

SEPMAG MONITOR (R&D software)

Sepmag LAB

Small tubes with different geometries using MLAB adaptors

Magnetic separation makes it possible to substitute filtration, centrifugation and separation techniques with a quick, efficient and clean process. At laboratory scale, SEPMAG® proprietary technology generates constant magnetic force patterns at their large bore, with minimum stray fields. This approach results in no aggregation issues, works with well defined magnetic separation conditions, and has the ability to handle different volumes.

For volumes from 1 to 50 ml, the SEPMAG® LAB series offers a combination of a strong separation force and easy re-suspension, which is especially suited to viscous media and/or small magnetic beads/particles.

Processes are monitored and recorded using the MONITOR hardware and software, which enables the operator to explore the effects of bead size, concentration or buffer conditions on the separation process.

Benefits

Explore, monitor and obtain data of your process

Easy comparison between processes and runs

Full recovery of material

Easy scalability

Work with viscous liquids and small particles

Safe